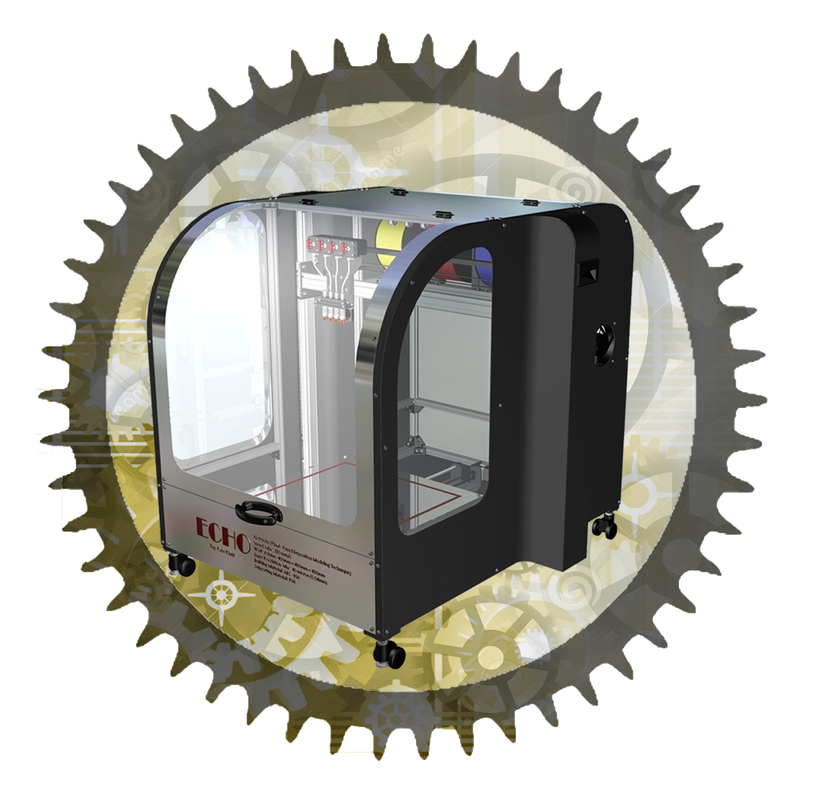

"ECHO" 3d Multi Color Printer Machine:

3D Multi Color Printer Machine:

|

CAD software used: Autodesk Inventor 2018.

Download Scope: 3D CAD model (Autodesk Inventor files), STEP. Price: 25$

The "ECHO" machine is a multi-color 3D printer designed using additive manufacturing techniques for rapid prototyping, specifically Fused Deposition Modeling (FDM). Like all 3D printers, the CAD file of the part to be printed as a 3D object is exported with an STL extension. This extension allows the 3D printer program to view the part as accumulative geometric surfaces, similar to the surfaces resulting from Finite Element Analysis (FEA). Using the 3D printer program, the part can be converted to many tiny slices, and then these slices are sent successively to the 3D printer machine so that the part can be built slice by slice until the full 3D part is completed, resulting in a part that is identical to the modeled part in the CAD program.

For building the part, the FDM technique relies on melting a thermal polymer that pours out of the actuator head nozzle. The actuator head traces the cross-section of the processed slice and builds according to it until the full completely of the slice section. The procedure is repeated many times to complete the part building. To support the built part body in case of balance adjusting during the building process, another thermal polymer is used as a supporting material to fill all part gaps. After the building end, the support material is removed, and we are left with a part or a product built from just the building material. In this printer, the thermal polymer used is Acrylonitrile butadiene styrene (ABS), which melts between 180 and 220 degrees Celsius, and it is provided in the markets as filaments coiled around a roll. The used filament diameter is 1.75mm, and ABS filaments come in a variety of colors (in this machine, blue, red, and yellow are used as building materials). The supporting material used is Polyvinyl acetate (PVA), which also melts between 180 and 220 degrees Celsius. It is provided in the markets as filaments coiled around a roll, with a diameter of 1.75mm, and is often found in white color (the roll located at the right side of the machine). An important feature of this material is its ability to dissolve into water. Consequently, after building the part, it is enough to submerge it in water, and the supporting material will dissolve, leaving only the building material. Both building and supporting materials are provided to the actuator head nozzle by means of a feeding mechanism, which consists of a feeder that pulls in the plastic filament from the roll and then guides it into a canal that ends with the melting chamber, which is in touch with a ceramic heater (40 watts). The material is melted and poured out through the nozzle, which has an orifice with a diameter of 0.5mm. The feeding mechanism includes an aluminum cooler to prevent the heat from transferring toward the top. There are four actuator heads and feeders in total (three actuator heads for building and one for supporting). The heat exchange can be done for the four coolers by two fans behind the actuator heads. The feeders are run by stepper motors (one for each one). Regarding the mechanical design side, this machine has three axes (X, Y, Z). It depends on moving the actuator head along the Y axis, which represents the machine gantry, using a motion method consisting of a stepper motor and high-accuracy synchronous pulleys and belt. The motion of the Y axis vertically along the Z axis is achieved by means of a pair of ball screws located on either side of the machine. As for the X axis, it represents the motion of the work table to the front or back using a stepper motor and synchronous pulleys and belt. In all axes, guiding mechanisms are used consisting of rails with a V shape, and wheels with V-shaped grooves move on them. In the X axis, in addition to the previous guiding mechanism, there is a cylinder guider called a "Ball Spline" used to add more support for the table. The work volume or field for this machine is 40cm x 40cm x 40cm. 2cm is added to each axis as a margin, represented by the width of the square line on the work table. Regarding the dynamic analysis, the inertia forces and torques were studied, along with the maximum and minimum velocity required to move the actuator head. Consequently, stepper motors were chosen, with the number of them equal to the number of axes. These motors rotate 0.9 degrees with each pulse they receive and are characterized by high accuracy. The value of rotation will be taken into consideration to determine the printer accuracy, and the load torque for each motor is 4.4 Kg.cm. The building speed according to the Y axis is a maximum of 150 mm/s. On the other hand, the motion according to the X and Z axes is done by pulses. The motion accuracy for the X and Y axes is 30 microns, and the thickness of each layer is 20 microns as the maximum accuracy in this 3D printer machine. The machine is provided with four leveling feet with wheels. The purpose of the wheels is for easy transportation, and the purpose of the leveling feet is to make the work table parallel to the X and Y axes. |

|