Eng. RamiKhalil

Summary:

A result-focused and objective-driven mechanical design engineer with extensive international experience has evolved into a mechanical design consultant and machine designer expert, specializing in oil & gas downhole circulation and drilling tools, complex mechanical systems and automation, subtractive and additive manufacturing, deep hole drilling technologies, CNC machines, and robotics. Strong theoretical and practical fundamentals and principles support the effective ability to manage various projects related to complex mechanical systems and mechanisms, building a diverse skill set as a professional mechanical design engineer. Exceptional interpersonal skills facilitate the delivery of exceptional results for clients and organizations, evidenced by a successful portfolio.

Primary duties entail spearheading the design and production processes, providing high-reliability solutions that are commonly used for machines and oil & gas, and ensuring project compliance with the most recent standards such as oil & gas standards (API and DS-1) for extreme conditions such as shock, vibration, and temperature.

Highly skilled in executing the entire project planning and delivery cycle, including identifying technological advancements, conducting market research and analysis, conceptual design and verification, producing prototypes, assembling, testing and conducting evaluations, mentoring, and directing delivery teams, setting R&D goals, and selecting and sourcing of complex systems (mechanical, hydraulic, pneumatic, etc.) that can withstand harsh conditions.

Primary duties entail spearheading the design and production processes, providing high-reliability solutions that are commonly used for machines and oil & gas, and ensuring project compliance with the most recent standards such as oil & gas standards (API and DS-1) for extreme conditions such as shock, vibration, and temperature.

Highly skilled in executing the entire project planning and delivery cycle, including identifying technological advancements, conducting market research and analysis, conceptual design and verification, producing prototypes, assembling, testing and conducting evaluations, mentoring, and directing delivery teams, setting R&D goals, and selecting and sourcing of complex systems (mechanical, hydraulic, pneumatic, etc.) that can withstand harsh conditions.

Specializations:

Oil & Gas - Robotics - Additive Manufacturing (3D Printing and Rapid Prototyping Techniques) - CNC Machine Design - Finite Elements Analysis (FEA) - Computational Fluid Dynamics (CFD) - Static, Kinematic and Dynamic Analyses - CAD/CAM - Industrial Automation - Pneumatic and Hydraulic Systems - Product Design and Development - Production Planning - Project Management.

Visit Card:

Services:

|

Our services include the study and design of customized projects involving the mechanical systems of computer numerical control (CNC) machines. This may entail designing water cutting systems (water jets), laser cutting and engraving systems, additive manufacturing, and 3D printing systems.

|

We offer the study and design of custom projects related to the mechanical systems of industrial robots, which have either open-chain kinematics (series industrial robots) or closed-chain kinematics (parallel industrial robots).

|

In addition to our custom project services, we provide mechanical design services to our clients and final-year engineering students, such as 3D mechanical modeling, product design, and drafting. Furthermore, we support engineering students with their graduation projects and scientific research.

|

New!:

|

|

The "Torbot" mobile robot, with its simple four-wheeled design, has a wide range of potential applications. These may include use in dangerous environments, such as in space science or other hazardous fields. Additionally, it may be utilized for military purposes, such as for reconnaissance or other specialized operations.

|

Projects:

Publications:

New!:

Robotics: Mechanics, Mathematical Analysis and Control

|

About The Book:

This book provides a mathematical introduction to the mechanics and control of robots that can be modeled as kinematic chains. Topics covered include the concept of a robot’s configuration space and degrees of freedom, static grasp analysis, the description of rigid body motions, kinematics of open and closed chain robots, dynamics of open chain robots, and the basics of robot control. The emphasis is not on the latest research trends and technological innovations in robotics, but on learning the fundamental concepts and core principles that underlie robotics as a scientific discipline. The intent is to help the reader acquire a unified set of analytic tools for the modeling and control of robots, together with a reliable physical intuition that recognizes the unique and interdisciplinary nature of robotics. ISBN-13: 978-620-2-35681-7. ISBN-10: 6202356812. EAN: 9786202356817. |

Courses:

Ongoing Course:

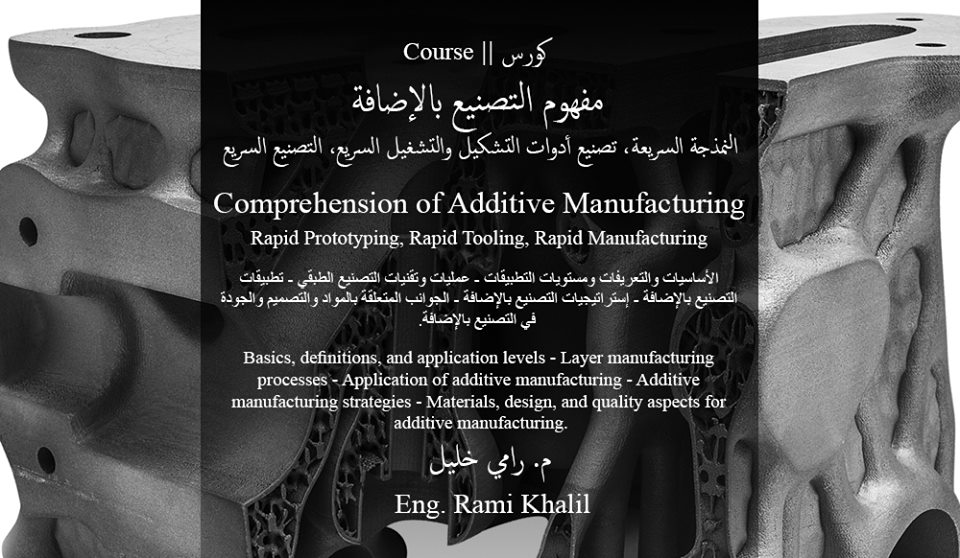

Comprehension of Additive Manufacturing - Rapid Prototyping, Rapid Tooling, and Rapid Manufacturing:

|

The course will include the following aspects:

1- Basics, definitions, and application levels. 2- Layer manufacturing processes. 3- Application of additive manufacturing. 4- Additive manufacturing strategies. 5- Materials, design, and quality aspects for additive manufacturing. The course will consist of a large number of short-period videos. Although these videos will be short, they will be full of ideas and information, and will be supported by illustrative photos, tables, and figures to clarify the concepts properly. |

Lectures:

New!

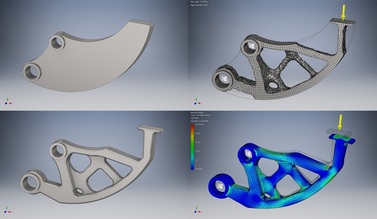

Machine Design – Topology Optimization: practical example using “Shape Generator” new tool in Autodesk Inventor Professional 2017:

|

In this practical lecture, I will provide you with a detailed explanation of how to apply the concept of topology optimization using the "Shape Generator" tool, a new feature added by Autodesk company to its package of Inventor Professional 2017 for 3D engineering design.

|

Contributions: |

The Library:

|

Social Media:

|

|

Youtube |