Information and expertizes have spread all over the internet in form of videos and articles, showing how easily anyone can print the products simply through CAD modeling and pushing the print button. But, if you are into design and manufacturing, you’re probably guessing that there’s more to it.

And you’re right; there are few important things to know more about the additive manufacturing technology, if you’re seriously planning to develop products through this technology in near future.

And you’re right; there are few important things to know more about the additive manufacturing technology, if you’re seriously planning to develop products through this technology in near future.

Software for Rapid Prototyping:

Software technology plays a crucial role in additive manufacturing process, and is constantly evolving to compliment the advancing 3D printing capabilities of the printer. The use of software spans across the additive manufacturing lifecycle right from sourcing ideas, designing the model and providing formatted data to printers, to monitoring and managing the printing process. It serves as an important link, enabling interfaces between computers and printers to allow entire 3D printing ecosystem to function efficiently.

In general, printing a part require 4 different software to ensure accuracy, reduced cost and quality. Also, special software packages are also required to convert solid geometries to lattice structures along with tools to perform simulations.

The journey from idea to the additive manufactured final part begins with sourcing the model either through rapidly growing 3D libraries or through 3D scanning techniques or through custom designs. This is followed by the design process where an exact 3D model of the product is prepared that will be printed, considering proper dimensions and geometrical accuracies. The next step is to optimize the geometry using software to suit the printing process and reduce material wastage. Finally, the software is also required to actually print the part and monitor the process to make print runs successful.

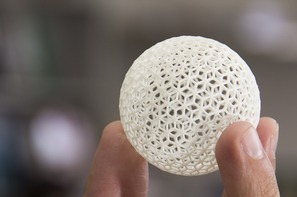

In general, printing a part require 4 different software to ensure accuracy, reduced cost and quality. Also, special software packages are also required to convert solid geometries to lattice structures along with tools to perform simulations.

The journey from idea to the additive manufactured final part begins with sourcing the model either through rapidly growing 3D libraries or through 3D scanning techniques or through custom designs. This is followed by the design process where an exact 3D model of the product is prepared that will be printed, considering proper dimensions and geometrical accuracies. The next step is to optimize the geometry using software to suit the printing process and reduce material wastage. Finally, the software is also required to actually print the part and monitor the process to make print runs successful.

CAD Modeling Process:

Unlike conventional modeling processes, developing 3D models for additive manufacturing requires a different approach. One of the important things to consider is the resolution of the geometry; too high resolution will consume more time to load and simultaneously print the part. On the contrary, a low-res model would develop prototype with poor quality. Moreover, the geometry to be developed is also material-sensitive.

As an example, products to be printed in plastic would require the dimensions of the holes in the design to be resized, as they would expand or contract during heating and cooling applications. Also, the geometry to be printed has to be thoroughly inspected for any open spaces and must be converted to “watertight”, to avoid errors in printing.

As an example, products to be printed in plastic would require the dimensions of the holes in the design to be resized, as they would expand or contract during heating and cooling applications. Also, the geometry to be printed has to be thoroughly inspected for any open spaces and must be converted to “watertight”, to avoid errors in printing.

Design Optimization:

Design optimization is a key to successful and cost effective utilization of additive manufacturing techniques. The purpose of using this advanced manufacturing technology is to reduce development cost and time, and thus, reducing material wastage during printing process remains a vital strategy. This requires the design engineers to understand the process of printing that requires rafts and supports to build the desired structure. Engineers have to identify a design that uses minimal support material that can also be removed easily once the part gets printed. Also, the design engineer must identify a balance between part density, strength and surface finish, and accordingly choose the material, printing speed and the used additive manufacturing technolgy.

To summarize, Right from sourcing the model, through designing and optimizing to monitoring printing process, the role of software is important across every step in the prototype or product development. Modeling methods require a good knowledge on the printing process, material to be used and the printing technology adopted.

Moreover, the need to optimize the design and apply lattice structures instead of solid geometry should be considered to reduce material consumption while maintaining the required strength of the product being developed. Successfully implementing rapid prototyping to gain the benefits of cost reduction and faster development schedules require manufacturers and engineers to adopt right processes and software technologies.

As such, 3D printing technology isn’t as easy as it seems. There’s so much more to it than simply creating a CAD model and pushing the print button.

To summarize, Right from sourcing the model, through designing and optimizing to monitoring printing process, the role of software is important across every step in the prototype or product development. Modeling methods require a good knowledge on the printing process, material to be used and the printing technology adopted.

Moreover, the need to optimize the design and apply lattice structures instead of solid geometry should be considered to reduce material consumption while maintaining the required strength of the product being developed. Successfully implementing rapid prototyping to gain the benefits of cost reduction and faster development schedules require manufacturers and engineers to adopt right processes and software technologies.

As such, 3D printing technology isn’t as easy as it seems. There’s so much more to it than simply creating a CAD model and pushing the print button.

RSS Feed

RSS Feed