Over the years, CAD systems have been evolved to serve as a link to reduce lead times and allow manufacturers to bring their products to the market faster. Neverthelesss, a combination of multiple approaches are utilized to effectively develop product designs with reduced lead time.

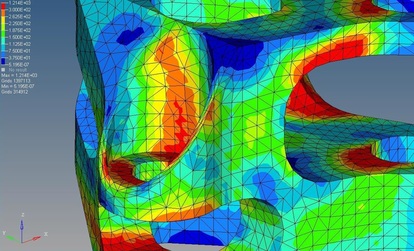

In many cases, manufacturing problems can be solved using computer CAD models and simulations; however, several cases can be best examined through physical tests.

Considering product design stage, CAD modeling is usually the approach engineers use; however, utilizing 3D scanning alongside can drastically reduce the modeling time required, which in turn can decrease the product development schedules.

Leading scanning software can be utilized to convert the point cloud data into a polygon model, which can then be used to create NURBS surface model to be utilized further in any modern 3D CAD system such as SolidWorks or Inventor.

The hybrid 3D modeling approach (utilizing 3D CAD and 3D scanning together) can provide multiple benefits over conventional 3D modeling:

The digital shape sampling and processing (DSSP) approach helps leverage the capabilities of existing CAD systems and simultaneously assists in reducing the design time required.

Incorporating the hybrid modeling approach for complex geometry modeling in usual reverse engineering projects can infuse new capabilities in existing CAD systems and leverage existing workflows to perform product designing more productively.

In many cases, manufacturing problems can be solved using computer CAD models and simulations; however, several cases can be best examined through physical tests.

Considering product design stage, CAD modeling is usually the approach engineers use; however, utilizing 3D scanning alongside can drastically reduce the modeling time required, which in turn can decrease the product development schedules.

Leading scanning software can be utilized to convert the point cloud data into a polygon model, which can then be used to create NURBS surface model to be utilized further in any modern 3D CAD system such as SolidWorks or Inventor.

The hybrid 3D modeling approach (utilizing 3D CAD and 3D scanning together) can provide multiple benefits over conventional 3D modeling:

- Replicating existing geometries becomes easier by coupling 3D measurement and CAD to build parametric models. The resulting time required to build the model can be reduces drastically. Complex models can be developed in hours that would otherwise require days or weeks through conventional modeling.

- Complex geometries can be developed quicker as compared to conventional CAD modeling. Since through 3D scanning, complex shapes can be produced easily, the time required to manually measure the dimensions and tweak the design using CAD tools can be eliminated, reducing the development time significantly.

- Existing CAD system can be leveraged rather than investing in new systems, allowing manufacturers to work on a familiar platform that most employees are comfortable to work with. This prevents manufacturers from investing in new CAD systems and figure out new possibilities with the existing one.

- Developing a CAD model through digital shape sampling and processing is much more accurate then measuring the dimensions manually, reducing the possibility of errors in the 3D model being developed.

- Lead time required to develop the digital model is reduced considerably, improving the overall product development efficiency and providing the manufacturers the ability to bring products to the market faster.

The digital shape sampling and processing (DSSP) approach helps leverage the capabilities of existing CAD systems and simultaneously assists in reducing the design time required.

Incorporating the hybrid modeling approach for complex geometry modeling in usual reverse engineering projects can infuse new capabilities in existing CAD systems and leverage existing workflows to perform product designing more productively.

RSS Feed

RSS Feed