Auxetic materials are a class of meta-materials which exhibit negative Poisson’s Ratio (Meta-materials are a class of man-made materials that have been specially and artificially engineered to contain small inhomogeneities which alter the properties on a macroscopic level). They have been known for over a hundred years but have only gained attention in recent decades. They can be single molecules, but more often they consist of an engineered material with a particular structure on the macroscopic level. Auxetic materials can occur in nature, but they are very rare. For example, some rocks and minerals demonstrate auxetic properties as does the skin on a cow’s teats.

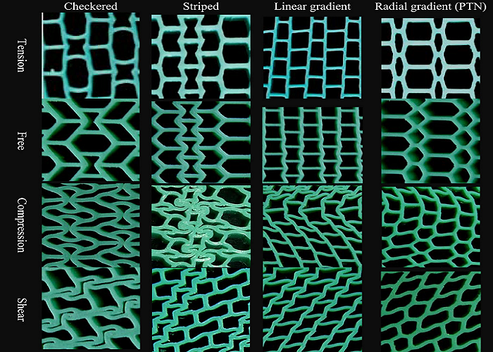

Auxetics are created by modifying the macrostructure of the material so that it contains hinge-like features which change shape when a force is applied. If a tensile force is applied the hinge-like structures extend, thus causing lateral expansion. If a compressive force is applied the hinge-like structures fold even further causing lateral contraction.

A common analogy used to describe the behavior of auxetic materials is to consider an elastic cord with an inelastic string wrapped around it. When a tensile force is applied the inelastic material straightens at the same time as the elastic cord stretches, thus effectively increasing the volume of the structure.

Auxetic materials are often based on foam structures and as such they have a relatively low density. It is this open cell structure which can be modified to give the desired properties.

The unusual properties of auxetic materials mean that they are relatively resistant to denting. When an auxetic is hit the compression caused by the impact results in the material compressing towards the point of the impact, thus becoming much denser and resisting the force. Auxetic materials are also more resistant to fracture; they expand laterally as a force is applied and this closes up potential cracks in the material before they start to grow. The main drawback of these materials is that they are often too porous, not dense enough or not stiff enough for load bearing applications and when these properties are adjusted the auxetic behavior tends to be reduced. Applications of these materials therefore often rely on a compromise of properties.

Auxetic materials can essentially be made in two different ways. In the top-down approach everyday polymers are manipulated to give the desired structure and properties. In the bottom-up approach the material is built up from scratch, molecule by molecule, allowing them to be engineered on a very small scale. In both cases the objective is to create a repeating pattern of building blocks or cells which contain the necessary hinge-like features.

There have been many suggested uses for auxetic materials, but most of these have yet to come to fruition commercially. These materials can be difficult to process on a large scale, making industrial manufacture difficult. Some potential areas for use are described below:

Biomedical applications

Many of the materials that are currently used in medical applications can be processed to exhibit auxetic properties. It has been suggested that auxetic materials could be used to dilate blood vessels during heart surgery. A piece of auxetic foam, possibly made from PTFE would be inserted into the blood vessel and then tension applied to this to cause lateral expansion and open out the vessel. Auxetics could also be used in surgical implants and prosthesis and for the anchors used to hold sutures, muscles and ligaments in place.

Filters

Traditional filters can be incredibly difficult to clean, leading to them being thrown away prematurely. A filter made from an auxetic foam could be cleaned much more easily by simply applying a tensile force to open up the pores. Once clean the force can be removed and the filter refitted.

Auxetic fibers

This is one area which does show real potential for exploitation. The key here is the development of a continuous process for developing auxetic materials in the form of fibers. The resulting fibers could be used in monofilament or multifilament form and could be knitted or woven together to make cloth. It has been suggested that these fabrics could be used in crash helmets, body armor and sports clothing where their dent and fracture resistance would be exploited.

Auxetic materials could also be added to metallic materials such as steels to create composites with improved resistance to cracking under shear strain (twisting).

Auxetics are created by modifying the macrostructure of the material so that it contains hinge-like features which change shape when a force is applied. If a tensile force is applied the hinge-like structures extend, thus causing lateral expansion. If a compressive force is applied the hinge-like structures fold even further causing lateral contraction.

A common analogy used to describe the behavior of auxetic materials is to consider an elastic cord with an inelastic string wrapped around it. When a tensile force is applied the inelastic material straightens at the same time as the elastic cord stretches, thus effectively increasing the volume of the structure.

Auxetic materials are often based on foam structures and as such they have a relatively low density. It is this open cell structure which can be modified to give the desired properties.

The unusual properties of auxetic materials mean that they are relatively resistant to denting. When an auxetic is hit the compression caused by the impact results in the material compressing towards the point of the impact, thus becoming much denser and resisting the force. Auxetic materials are also more resistant to fracture; they expand laterally as a force is applied and this closes up potential cracks in the material before they start to grow. The main drawback of these materials is that they are often too porous, not dense enough or not stiff enough for load bearing applications and when these properties are adjusted the auxetic behavior tends to be reduced. Applications of these materials therefore often rely on a compromise of properties.

Auxetic materials can essentially be made in two different ways. In the top-down approach everyday polymers are manipulated to give the desired structure and properties. In the bottom-up approach the material is built up from scratch, molecule by molecule, allowing them to be engineered on a very small scale. In both cases the objective is to create a repeating pattern of building blocks or cells which contain the necessary hinge-like features.

There have been many suggested uses for auxetic materials, but most of these have yet to come to fruition commercially. These materials can be difficult to process on a large scale, making industrial manufacture difficult. Some potential areas for use are described below:

Biomedical applications

Many of the materials that are currently used in medical applications can be processed to exhibit auxetic properties. It has been suggested that auxetic materials could be used to dilate blood vessels during heart surgery. A piece of auxetic foam, possibly made from PTFE would be inserted into the blood vessel and then tension applied to this to cause lateral expansion and open out the vessel. Auxetics could also be used in surgical implants and prosthesis and for the anchors used to hold sutures, muscles and ligaments in place.

Filters

Traditional filters can be incredibly difficult to clean, leading to them being thrown away prematurely. A filter made from an auxetic foam could be cleaned much more easily by simply applying a tensile force to open up the pores. Once clean the force can be removed and the filter refitted.

Auxetic fibers

This is one area which does show real potential for exploitation. The key here is the development of a continuous process for developing auxetic materials in the form of fibers. The resulting fibers could be used in monofilament or multifilament form and could be knitted or woven together to make cloth. It has been suggested that these fabrics could be used in crash helmets, body armor and sports clothing where their dent and fracture resistance would be exploited.

Auxetic materials could also be added to metallic materials such as steels to create composites with improved resistance to cracking under shear strain (twisting).

RSS Feed

RSS Feed