Definition:

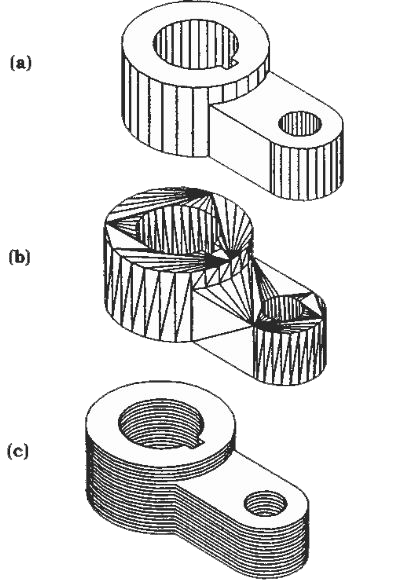

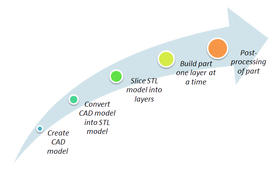

Additive fabrication refers to a class of manufacturing processes, in which a part is built by adding layers of material upon one another. These processes are different from subtractive processes or consolidation processes. Subtractive processes, such as milling, turning, or drilling, use carefully planned tool movements to cut away material from a workpiece to form the desired part. Consolidation processes, such as casting or molding, use custom designed tooling to solidify material into the desired shape. Additive processes, on the other hand, do not require custom tooling or planned tool movements. Instead, the part is constructed directly from a digital 3D model created through Computer Aided Design (CAD) software. The 3D CAD model is converted into many thin layers and the manufacturing equipment uses this geometric data to build each layer sequentially until the part is completed. Due to this approach, additive fabrication is often referred to as layered manufacturing, direct digital manufacturing, or solid free form fabrication.

The most common term for additive fabrication is rapid prototyping. The term "rapid" is used because additive processes are performed much faster than conventional manufacturing processes. The fabrication of a single part may only take a couple hours, or can take a few days depending on the part size and the process. However, processes that require custom tooling, such as a mold, to be designed and built may require several weeks. Subtractive processes, such as machining, can offer more comparable production times, but those times can increase substantially for highly complex parts. The term "prototyping" is used because these additive processes were initially used only to fabricate prototypes. However, with the improvement of additive technologies, these processes are becoming increasingly capable of high-volume production manufacturing.

The most common term for additive fabrication is rapid prototyping. The term "rapid" is used because additive processes are performed much faster than conventional manufacturing processes. The fabrication of a single part may only take a couple hours, or can take a few days depending on the part size and the process. However, processes that require custom tooling, such as a mold, to be designed and built may require several weeks. Subtractive processes, such as machining, can offer more comparable production times, but those times can increase substantially for highly complex parts. The term "prototyping" is used because these additive processes were initially used only to fabricate prototypes. However, with the improvement of additive technologies, these processes are becoming increasingly capable of high-volume production manufacturing.

Process Cycle:

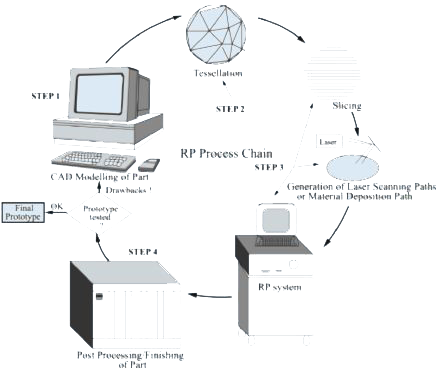

| Several different additive fabrication processes are commercially available or are currently being developed. Each process may use different materials and different techniques for building the layers of a part. However, each process employs the same basic steps, listed below.

|

Technologies:

The technologies that can be used to build a part one layer at a time are varied and in different stages of development. Some technologies are commercially available methods of fabricating prototypes, others are quickly becoming viable forms of production manufacturing, and newer technologies are continuously being developed. These different methods of additive fabrication can be classified by the type of material that is employed.

- Liquid based processes: These additive technologies typically use photocurable polymer resins and cure selected portions of the resin to form each part layer. The most common liquid-based additive process is Stereolithography (SLA), which was the first commercially available additive process. Parts produced using this technology offer high accuracy and an appearance similar to molded parts. However, photocurable polymers offer somewhat poor mechanical properties which may worsen over time. Other liquid-based processes include Jetted Photopolymer, which may use a single jet or multiple jets.

- Powder based processes: In powder based processes, such as Selective Laser Sintering (SLS), a selected portion of powdered material is melted or sintered to form each part layer. The use of powdered material enables parts to be fabricated using polymers, metals, or ceramics. Also, the mechanical properties of these parts are better and more stable than a photocured polymer part. Other powder-based processes include Direct Metal Laser Sintering (DMLS) and Three Dimensional Printing (3DP).

- Solid based processes: Solid based processes use a variety of solid, non powder, materials and each process differs in how it builds the layers of a part. Most solid-based processes use sheet stacking methods, in which very thin sheets of material are layered on top of one another and the shape of the layer is cut out. The most common sheet stacking process is Laminated Object Manufacturing (LOM), which uses thin sheets of paper, but other processes may use polymers or metal sheets. Other solid based processes use solid strands of polymer, not sheets, such as Fused Deposition Modeling (FDM) which extrudes and deposits the polymer into layers.

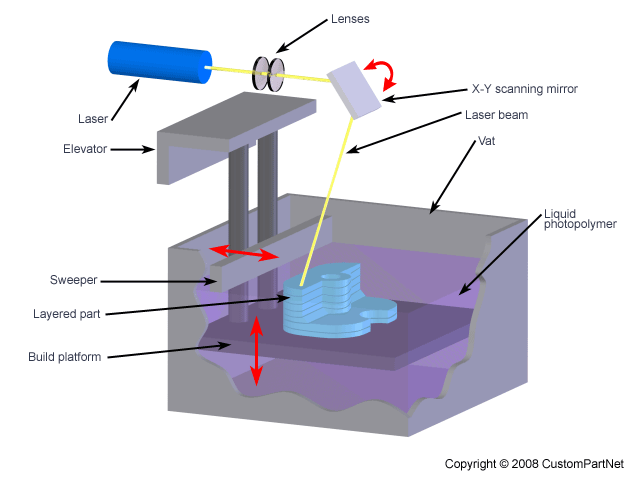

Stereolithography (SLA):

Stereolithography (SLA) is the most widely used rapid prototyping technology. It can produce highly accurate and detailed polymer parts. It was the first rapid prototyping process, introduced in 1988 by 3D Systems based on work by inventor Charles Hull. It uses a low-power, highly focused UV laser to follow cross-sections of a three-dimensional object in a container of liquid photosensitive polymer. As the laser follows the layer, the polymer solidifies and the excess areas are left as liquid. When a layer is completed, a leveling blade is moved across the surface to smooth it before depositing the next layer. The platform is lowered by a distance equal to the layer thickness (typically 0.05-0.007 mm), and a subsequent layer is formed on top of the previously completed layers. This process of following and smoothing is repeated until the build is complete. Once complete, the part is elevated above the container and drained. Excess polymer is swabbed or rinsed away from the surfaces. In many cases, a final cure is given by placing the part in a UV oven. After the final cure, supports are cut off the part and surfaces are polished, sanded or otherwise finished.

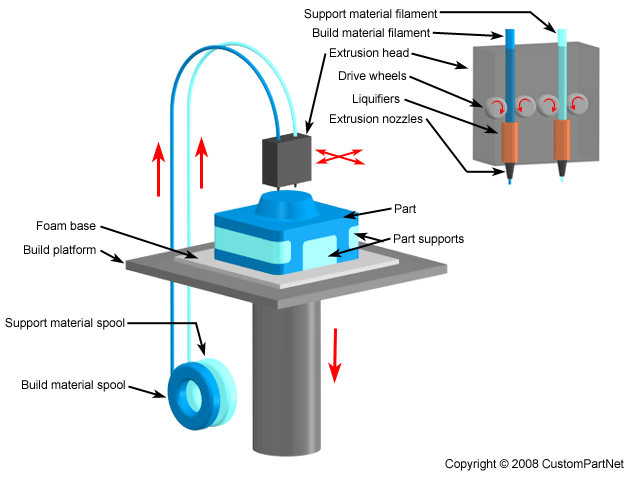

Fused Deposition Modeling (FDM):

Fused Deposition Modeling (FDM) was developed by Stratasys in Minnesota. In this process, a plastic or wax material is extruded through a nozzle that follows the part's cross sectional geometry layer by layer. The build material is usually supplied in filament form, but some setups utilize plastic pellets instead. The nozzle contains resistive heaters that keep the plastic at a temperature just above its melting point so that it flows easily through the nozzle and forms the layer. The plastic hardens immediately after flowing from the nozzle and bonds to the layer below. Once a layer is built, the platform lowers, and the extrusion nozzle deposits another layer. The layer thickness and vertical dimensional accuracy is determined by the extruder die diameter, which ranges from (0.1 to 0.3 mm). In the (X,Y) plane, (0.025 mm) resolution is achievable. A range of materials are available including ABS, polylastic, polyamide, polycarbonate, polyethylene, polypropylene, and investment casting wax.

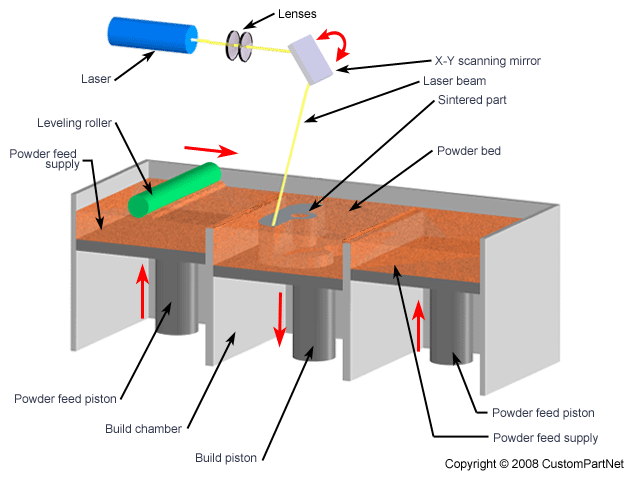

Selective Laser Sintering (SLS):

Selective Laser Sintering (SLS) was developed at the University of Texas in Austin, by Carl Deckard and colleagues. The technology was patented in 1989 and was originally sold by DTM Corporation. The basic concept of SLS is similar to that of SLA. It uses a moving laser beam to follow and selectively sinter powdered polymer and/or metal composite materials into cross sections of a three dimensional part. As in all rapid prototyping processes, the parts are built upon a platform that adjusts in height equal to the thickness of the layer being built. Additional powder is deposited on top of each solidified layer and sintered. This powder is rolled onto the platform from a bin before building the layer. The powder is maintained at an elevated temperature. Unlike SLA, special support structures are not required because the excess powder in each layer acts as a support to the part being built. With the metal composite material, the SLS process solidifies a polymer binder material around steel powder (100 micron diameter) one slice at a time, forming the part. The part is then placed in a furnace, at temperatures in excess of 900 °C, where the polymer binder is burned off and the part is infiltrated with bronze to improve its density. The burn-off and infiltration procedures typically take about one day, after secondary machining and finishing is performed. Recent improvements in accuracy and resolution, and reduction in stair-stepping, have minimized the need for secondary machining and finishing. SLS allows for a wide range of materials, including nylon, glass-filled nylon, SOMOS (rubber-like), Truform (investment casting), and the previously discussed metal composite.

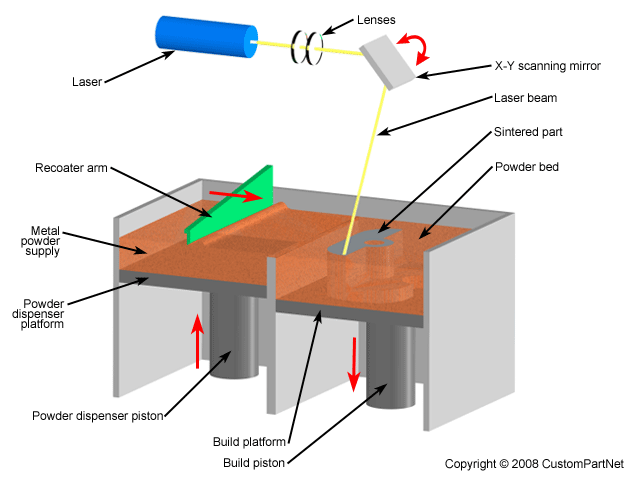

Direct Metal Laser Sintering (DMLS):

Direct Metal Laser Sintering (DMLS) was developed jointly by Rapid Product Innovations (RPI) and EOS GmbH, starting in 1994, as the first commercial rapid prototyping method to produce metal parts in a single process. With DMLS, metal powder (20 micron diameter), free of binder or fluxing agent, is completely melted by the scanning of a high power laser beam to build the part with properties of the original material. Eliminating the polymer binder avoids the burn-off and infiltration steps, and produces a 95% dense steel part compared to roughly 70% density with Selective Laser Sintering (SLS). An additional benefit of the DMLS process compared to SLS is higher detail resolution due to the use of thinner layers, enabled by a smaller powder diameter. This capability allows for more intricate part shapes. Material options that are currently offered include alloy steel, stainless steel, tool steel, aluminum, bronze, cobalt-chrome, and titanium. In addition to functional prototypes, DMLS is often used to produce rapid tooling, medical implants, and aerospace parts for high heat applications.

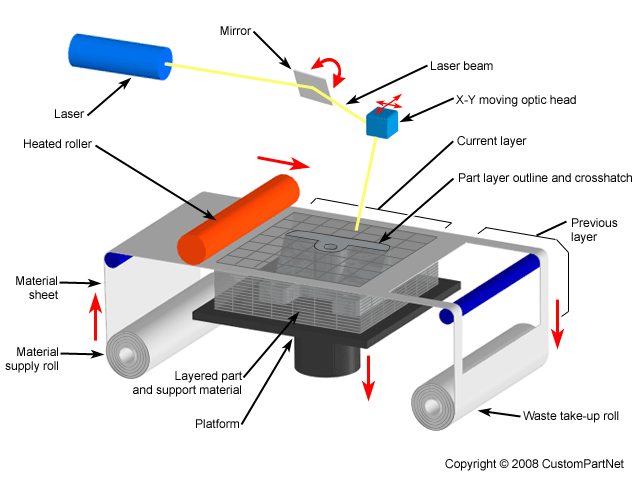

Laminated Object Manufacturing (LOM):

The first commercial Laminated Object Manufacturing (LOM) system was shipped in 1991. LOM was developed by Helisys of Torrance, CA. The main components of the system are a feed mechanism that advances a sheet over a build platform, a heated roller to apply pressure to bond the sheet to the layer below, and a laser to cut the outline of the part in each sheet layer. Parts are produced by stacking, bonding, and cutting layers of adhesive-coated sheet material on top of the previous one. A laser cuts the outline of the part into each layer. After each cut is completed, the platform lowers by a depth equal to the sheet thickness (typically 0.05-0.5 mm), and another sheet is advanced on top of the previously deposited layers. The platform then rises slightly and the heated roller applies pressure to bond the new layer. The laser cuts the outline and the process is repeated until the part is completed. After a layer is cut, the extra material remains in place to support the part during build.

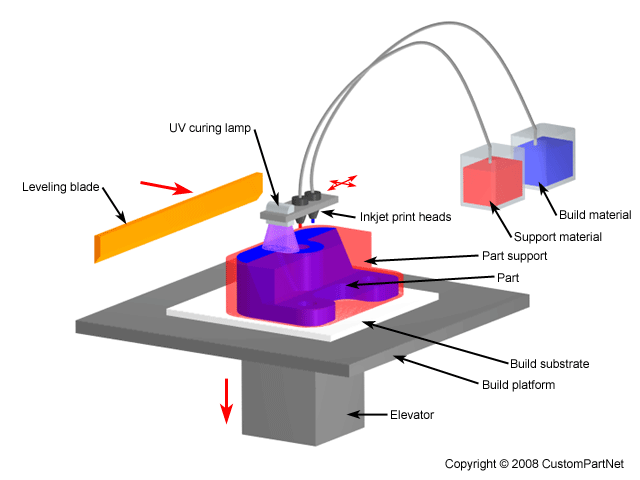

Jetted photopolymer:

Jetted photopolymer is an additive process that combines the techniques used in Inkjet Printing and Stereolithography. The method of building each layer is similar to Inkjet Printing, in that it uses an array of inkjet print heads to deposit tiny drops of build material and support material to form each layer of a part. However, as in Stereolithography, the build material is a liquid acrylate-based photopolymer that is cured by a UV lamp after each layer is deposited. For this reason, Jetted Photopolymer is sometimes referred to as Photopolymer Inkjet Printing. The advantages of this process are very good accuracy and surface finishes. However, the feature detail and material properties are not quite as good as Stereolithography. As with Inkjet Printing, the most common application of this technology is prototypes used for form and fit testing. Other applications include rapid tooling patterns, jewelry, and medical devices.

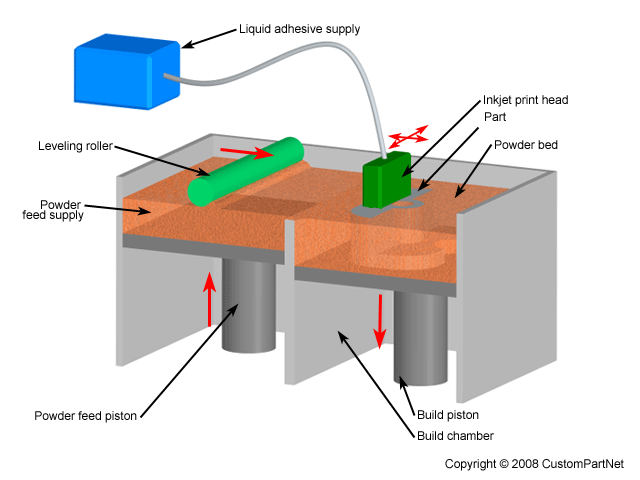

3D Printing:

Three Dimensional Printing (3DP) technology was developed at the Massachusetts Institute of Technology and licensed to several corporations. The process is similar to the Selective Laser Sintering (SLS) process, but instead of using a laser to sinter the material, an ink-jet printing head deposits a liquid adhesive that binds the material. Material options, which include metal or ceramic powders, are somewhat limited but are inexpensive relative to other additive processes. 3D Printing offers the advantage of fast build speeds, typically 2-4 layers per minute. However, the accuracy, surface finish, and part strength are not quite as good as some other additive processes. 3D Printing is typically used for the rapid prototyping of conceptual models (limited functional testing is possible).

The 3D printing process begins with the powder supply being raised by a piston and a leveling roller distributing a thin layer of powder to the top of the build chamber. A multi-channel ink-jet print head then deposits a liquid adhesive to targeted regions of the powder bed. These regions of powder are bonded together by the adhesive and form one layer of the part. The remaining free standing powder supports the part during the build. After a layer is built, the build platform is lowered and a new layer of powder added, leveled, and the printing repeated. After the part is completed, the loose supporting powder can be brushed away and the part removed.

The 3D printing process begins with the powder supply being raised by a piston and a leveling roller distributing a thin layer of powder to the top of the build chamber. A multi-channel ink-jet print head then deposits a liquid adhesive to targeted regions of the powder bed. These regions of powder are bonded together by the adhesive and form one layer of the part. The remaining free standing powder supports the part during the build. After a layer is built, the build platform is lowered and a new layer of powder added, leveled, and the printing repeated. After the part is completed, the loose supporting powder can be brushed away and the part removed.

Addictive MAnufacturing Advantages:

Additive fabrication offers several advantages, listed below:

- Speed: As described above, these "rapid" processes have short build times. Also, because no custom tooling must be developed, the lead time in receiving parts is greatly reduced.

- Part complexity: Because no tooling is required, complex surfaces and internal features can be created directly when building the part. Also, the complexity of a part has little effect on build times, as opposed to other manufacturing processes. In molding and casting processes, part complexity may not affect the cycle times, but can require several weeks to be spent on creating the mold. In machining, complex features directly affect the cycle time and may even require more expensive equipment or fixtures.

- Material types: Additive fabrication processes are able to produce parts in plastics, metals, ceramics, composites, and even paper with properties similar to wood. Furthermore, some processes can build parts from multiple materials and distribute the material based on the location in the part.

- Low-volume production: Other more conventional processes are not very cost effective for low-volume productions because of high initial costs due to custom tooling and lengthy setup times. Additive fabrication requires minimal setup and builds a part directly from the CAD model, allowing for low per-part costs for low-volume productions.

RSS Feed

RSS Feed