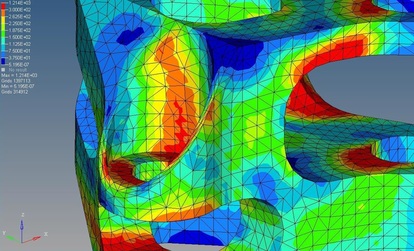

Example of FEA Resuts

Example of FEA Resuts However, FEA cannot be neglected as it helps in achieving comprehensive product behavior under loading even for complex geometries for which approximations are better than knowing nothing. The validity of FEA results however is purely a judgment that is based on the knowledge of the analyst performing the simulation. It is purely his expertise and accurate application of boundary conditions with required assumptions that yields a meaningful result through FEA approach.

Any FEA solver or a software package available today incorporates number of functions and variables which include force, mass, velocity, acceleration, heat flux, stress-strain, displacement and other dynamic loads, with each load case requiring a separate analysis.

However, modern simulation tools have become much easier allowing non-experts to easily model the problem. The results obtained however are required to be justified. An inexperienced engineer might consider the results valid whereas an experienced analyst might consider adding few more elements across critical regions of the geometry and refine the results further.

While FEA helps in reducing number of prototyping trials and manual calculations, the results are still required to be verified with a physical experiment to ensure the solvers reliability. It is quite easy to build a neat and colorful FEA model through several computational iterations but with no meaningful value. It is always good to perform simple hand calculations in the beginning before going for a simulation run.

Later, when the FEA results show dramatic increase in the values, it can be easily identified that something is wrong with the simulation or the boundary conditions might not have been defined properly.

Regions with complex geometry such as edges, chamfers, holes or curves can be easily neglected by an inexperienced engineer. An expert would rather consider the ones critical to the design aspect and apply fine mesh on those regions to ensure that the physics are captured accurately.

It is also crucial to carry out mesh sensitivity analysis by performing same FEA load case with different mesh quality and element types to realize that the solution has the potential to give accurate results without further mesh refinement required.

When in the right hands, FEA can save months in the product design and development stage by providing required information early. Prototyping trials can be reduced considerably with a subsequent reduction in development costs.

However, it is important to realize that the tool will only be as good as the operator using it. It is thus the ability and experience of the analyst that decides the quality of FEA results and not the expensiveness of the software package that promises accuracy.

RSS Feed

RSS Feed