Definition:

Brief History:

Dr. Mohamed Hashish

Dr. Mohamed Hashish To ask Dr. Hashish for every thing related to waterjet technologies, go to the link below:

http://www.flowwaterjet.com/en/ask-dr-hashish.aspx

Pure And Abrasive Waterjets:

Pure Waterjets:

Samples

Samples Abrasive Waterjets:

Samples

Samples How does WAterjet Works?

HIGH PRESSURE PUMP:

The Intensifier Principle:

Pressure generation:

The two piston rods installed in the hydraulic piston apply pressure to the water in the two high pressure cylinders of the intensifier. These are part of the secondary water circuit. Suitably dimensioned check valves on both ends of the high pressure cylinders control the input of fresh water into the cylinders and the supply of cutting water to the pump outlet. The water pressure of approx. (6200 bar) is generated through a piston surface ratio of around (38:1). The high pressure pumps are equipped with an accumulator (pressure peak compensator) that ensures that the high pressure signal at the outlet of the high pressure pump remains more or less constant during the change of direction of the hydraulic piston. The high pressure pump is connected through a high-strength stainless steel pipe to the cutting head. The sapphire or diamond orifice in the cutting head focuses the pressure into an ultrafast waterjet (speeds of approx. 800 to 1000 m/s).

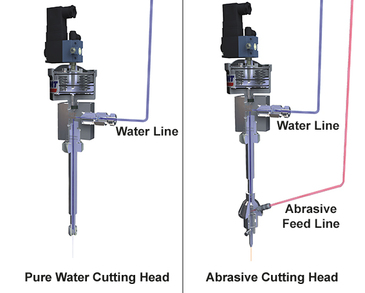

To cut hard materials, the cutting power of the waterjet can be increased by adding an abrasive. In such units, abrasive, water and air are mixed in the mixing chamber of the cutting head, collimated in the focusing nozzle and accelerated. The resulting high-energy jet is capable of micro-eroding, i.e. drilling and cutting, materials of great thicknesses and of the most diverse consistencies, such as metals, ceramics, rock and bulletproof glass.

Cutting head And Nozzle:

Pure Water Cutting Heads:

Abrasive Cutting Heads:

Video:

REFERENCES:

- KMT Technology user manuals and website.

- BHDT Technology manuals.

- FLOW Waterjet technology database.

- Wikipedia.

RSS Feed

RSS Feed